Precision Engineering in Rotary Indexing Table Design #

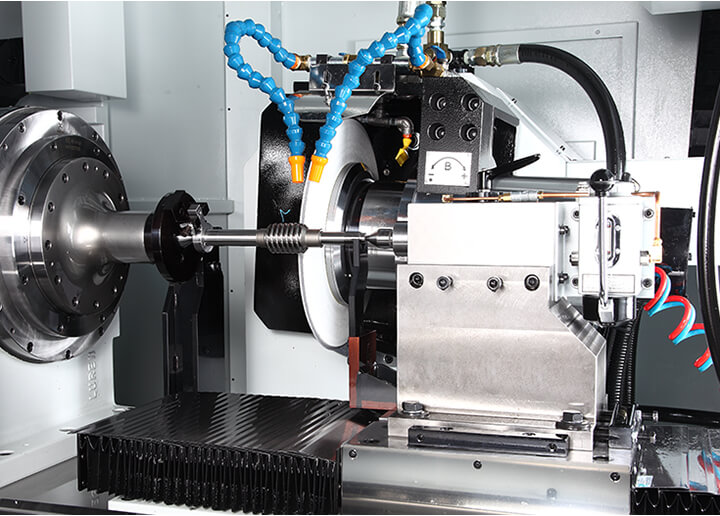

Tanshing is dedicated to advancing the technology and design of rotary indexing tables, focusing on high torque, accuracy, and performance. Our commitment to innovation is reflected in our investment in high-precision CNC worm-gear grinding machines, enabling us to maintain strict control over component accuracy and deliver products of the highest quality.

Dual Lead Worm Drive: Features and Benefits #

- The worm-wheel is crafted from a specialized aluminum bronze alloy, incorporating over ten elements such as Sn, Zn, Pb, Fe, Ni, Al, P, Mn, Aa, and Cu. This composite material offers high tensile and compressive strength, oxidation resistance, toughness, and abrasion resistance. It achieves a tensile strength exceeding 650N/mm², elongation of 15% or less, and hardness above HB180. Wear consumption is measured at 26.3mg/cm² per 10,000m.

- The development of the “indexable dual lead worm” design results in deeper teeth contact and a larger contact area, allowing the system to bear greater thrust, increase rigidity, and reduce wear on the worm-wheel.

- To ensure consistent high-precision, worm machining equipment is regularly updated and replaced. Under normal conditions, the system maintains its accuracy for 10 to 15 years before adjustment is required.

Backlash Adjustment for Long-Term Accuracy #

Over time, the dual lead worm’s thread—designed with varying pitches—may introduce backlash between the worm wheel and gear. Tanshing addresses this by allowing longitudinal adjustment of the worm, preserving the highest indexing accuracy on the work table. (Patent number 098511)

Full Circular Hydraulic Clamping System #

The full circular hydraulic clamping system utilizes a clamping sleeve to secure the entire disc via hydraulic pressure. By distributing the clamping force around the entire circumference, this system achieves higher clamping strength than conventional pneumatic systems and prevents disc surface deformation, ensuring accuracy is maintained.

Rigorous Quality Inspection #

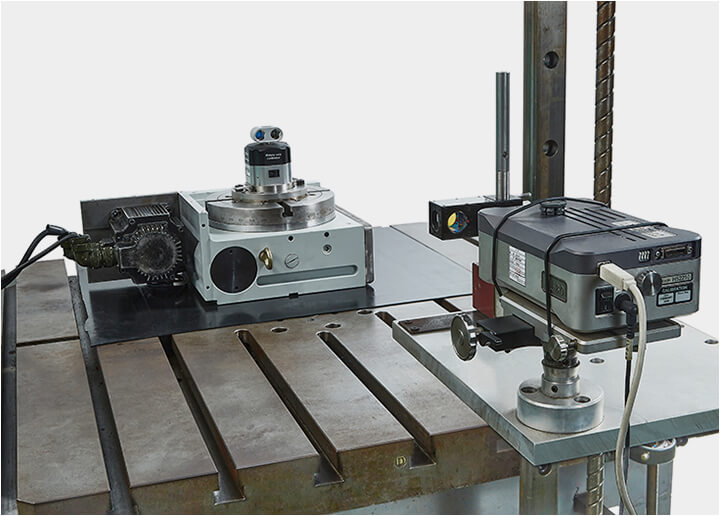

- Tanshing has made significant investments in high-precision inspection equipment, including coordinate measuring machines (CMMs) and laser interferometers, establishing comprehensive quality inspection processes.

- The inspection team has been expanded to integrate quality systems, with detailed checklists for each assembly process. All products undergo strict control by senior staff prior to delivery.

Coating Quality and Waterproofing #

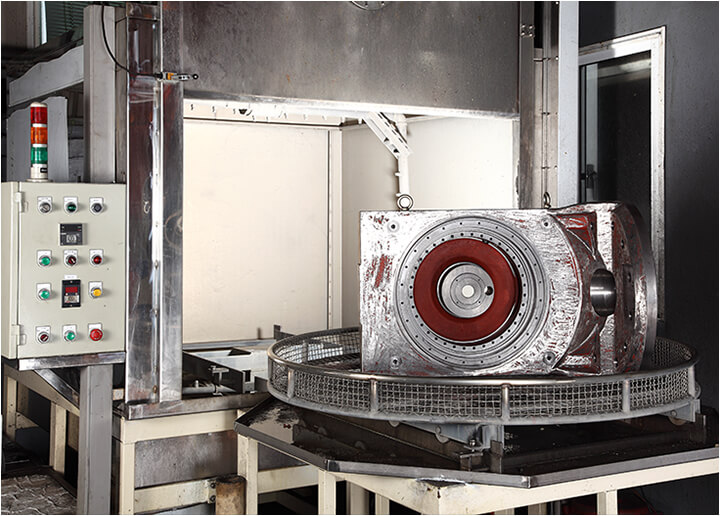

- Tanshing’s waterproofing design matches the standards of leading Japanese brands. Standard machines feature a positive pressure drainage connector, achieving a waterproof rating of up to IP66 (IP65 without the drainage function).

- The painting process is inspired by European automotive standards, involving manual surface treatment, high-pressure hot water cleaning, putty application, primer, and a high-hardness, scratch-resistant topcoat.